Our customers need improved, lower-cost oxidation methods for ultrapure, process, and wastewater recycling applications to remove organics and for microbial elimination. The Symbios TPR4000™ is the solution that can increase productivity and product quality for manufacturing processes, improve water treatment economics for utilities, provide new wastewater, improve efficacy and economics of existing processes, and facilitate flowback and produced water cleanup and agricultural reuse for oil & gas extraction wastewaters.

The Symbios TPR provides lower-cost, higher performance, more effective disinfection, and is able to remove emerging contaminants, reduce RO fouling and costs, and reduce post-MBR odor and residual organics when compared to established, chemical additive treatment and traditional advanced oxidation processes.

Technology Overview:

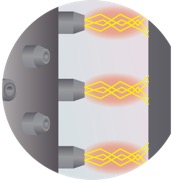

Illustration of TPR design and operation

The patented Symbios TPR™ Plasma Oxidation System is a low-power, plasma-based advanced oxidation technology. The unique design of the TPR combines a continuous mixing mechanism with an air-enhanced plasma discharge system. Contaminated water enters from the top into the treatment chamber and is turbulently mixed and constantly exposed to the plasma nozzles. A low voltage is applied across the plasma nozzle and the discharge area while the plasma nozzle spindle continuously rotates and discharges under the support of air. The resulting plasma oxidation products are purged out of the chamber into the air as trace amounts of carbon dioxide (CO2).

The unique design of the TPR4000 includes a negatively-charged cathode at the core of the apparatus with electrode pins protruding out toward an outside, positively-charged anode cylinder wall and is spun at 1000 rpm. While the cathode is spinning, the contaminated water is introduced at one end and exits out the other end and low voltage plasma is formed between all the pins and anode wall. The plasma produces high-energy electrons and interacts with water to produce hydroxyl radicals that effectively oxidize organic contaminants and convert them into carbon dioxide (CO2). Not only has this new design proved effective in treating water, but it is scalable (in length of the tube and diameter) in continuous water flow mode and can be expanded with parallel reactors to treat even larger volumes of water.

Product Features:

- Nonthermal plasma oxidation system

- Microbial and organic contamination control without chemicals

- Requires only air and electricity to directly and continuously treat and disinfect process waters and wastewater

- Proven aggressive oxidation of a variety chemical compounds and microbials at very facile kinetics due to the volumetric plasma facilitated by the patented spinning rotor, hollow electrodes with air flow and frits to create nanobubbles, and turbulent mixing of gas and water phases.

- Low energy consumption and automated flow-through design are scale- and process-friendly

- Modeling indicates the TPR will outperform competitive technologies at scaleup where the scaled-up modules with more electrodes uses nearly the same electricity demand (300-400W)

- Residual peroxone disinfectants for downstream control of microbial regrowth

- Multi-mode action using UV light, radical oxygen species, and low-level oxidants (hydrogen peroxide, ozone, and others)

- Tunable, modular, and scalable to your application

- Low-power and compressed air requirements for seamless integration into your facility

- Automated and microprocessor-controlled with a user-friendly control interface

- In-line monitoring of effluent quality and composition

- Complete computer-automated rack enclosure with included safety features

Benefits:

- A safer alternative to acid and chlorine-based chemical additives

- No toxic byproducts – all components naturally break down to water and oxygen

- Cost effective, eco-friendly, and energy-efficient

- Adaptable to variable influent waters

- Capacity to handle high levels of dissolved and suspended solids