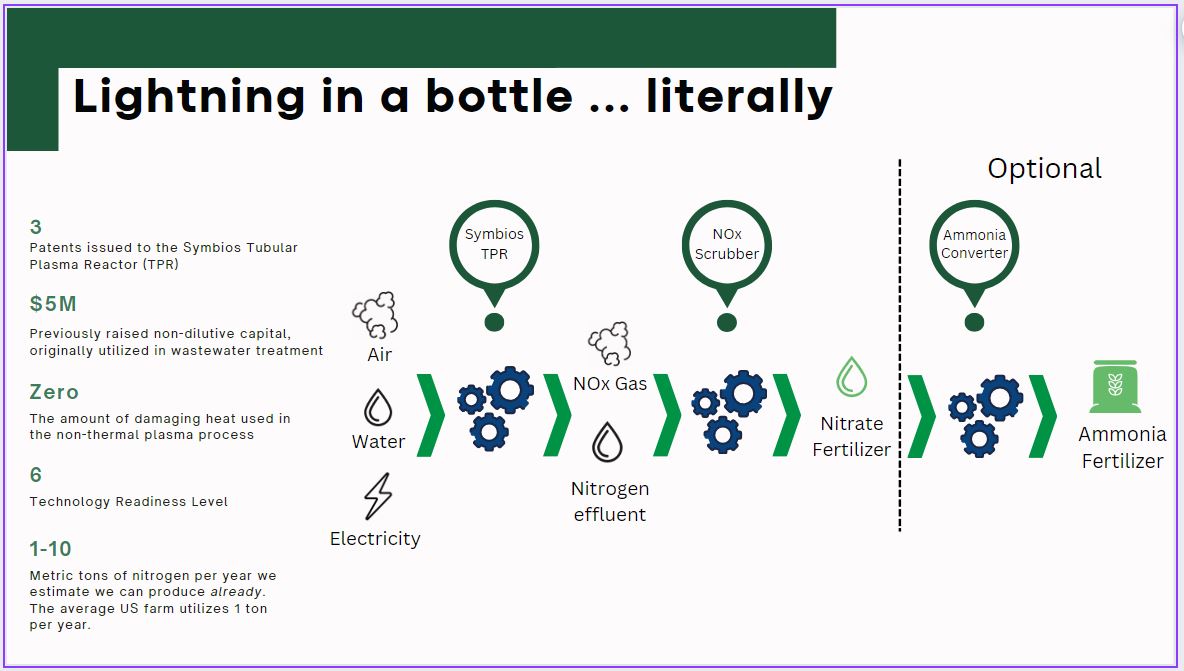

Our customers need improved, lower-cost nitrogen fertilizer that is decoupled from the price of fossil fuels, able to be applied through existing equipment more sustainably without waste and polluting runoff, and decentralized from the supply chain. The Symbios Tubular Plasma Reactor (TPR™) is the solution that can produce inexpensive nitrogen fertilizer for a farmer right in their backyard.

The concept is simple. Nitrogen makes up roughly 78% of the ambient air. Our machine draws in air and converts the available nitrogen into a usable nitrogen fertilizer product through a plasma reactor system that effectively creates a controlled lightning storm in a cylinder. The only inputs are air, water, and electricity.

Technology Overview:

Illustration of TPR design and operation

The patented Symbios TPR™ is a low-power, plasma-based advanced oxidation technology. The unique design of the TPR combines a continuous mixing mechanism with an air-enhanced plasma discharge system. Water enters from the top into the treatment chamber and is turbulently mixed and constantly exposed to the plasma nozzles. A low voltage is applied across the plasma nozzle and the discharge area while the plasma nozzle spindle continuously rotates and discharges under the support of air. The resulting plasma oxidation products are usable activated forms of nitrogen that can be converted through standardized steps into liquid nitrate fertilizer or ammonia.

Not only has this new design proved effective in producing the ingredients for fertilizer and already developed to on-farm commercial scale, but it is scalable (in length of the tube and diameter) in continuous water flow mode and can be expanded with parallel reactors to create larger volumes of fertilizer.

Product Features:

- Nonthermal plasma oxidation system

- Requires only air, water, and electricity to directly and continuously create activated nitrogen fertilizer

- Modular and scalable to your application

- Low-power and compressed air requirements for seamless integration into your facility

- Automated and microprocessor-controlled with a user-friendly control interface

- Complete rack enclosure with included safety features

- In-line monitoring of effluent products

Benefits for the farmers

- Lower-priced nitrogen fertilizer

- Applied as liquid through existing equipment with smart fertilization over time

- Decoupled from the cost of fuel

- Autonomy from the supply chain

- Improved soil health and reduced water and air pollution